EL-BJÖRN CONNECT

EL-BJÖRN CONNECT

Our intelligent temporary BMS system that provides remote monitoring and control your El-Björn climate and power distribution products.

Our intelligent temporary BMS system that provides remote monitoring and control your El-Björn climate and power distribution products.

EL-BJÖRN CONNECT

INDUSTRY LEADING BUILDING MANAGEMENT SYSTEM

El-Björn CONNECT is our Temporary Building Management System, offering remote monitoring of temporary climate control and power distribution units, all from one easy to use online portal.

El-Björn Connect provides the foundation for long-term improvement. It gives you easy access to consumption figures for the entire project as well as individual circuit metering. The alert features and online access help to safeguard the energy supply to the project, as well as simplifying troubleshooting if there is a problem. This provides opportunities to increase productivity through better planning, preventive action, continuous improvement and process optimization, which lead to lower energy use and lower overall costs.

Benefits of El-Björn CONNECT:

Instant Data

View real time and historical performance data from your CONNECT compatible products, allowing you to better manage the output of your climate and power distribution.

Remotely Control

Update the output power, temperature and fan speed of your El-Björn TF EBC machines remotely from your personal CONNECT portal.

Easy to use

We personalise your online portal to make viewing your data as easy as possible. Based on your data gathering requirements, we can create graphs and display machine locations to understand your site performance.

Cost Savings

Use reported machine data to quickly identify areas of excess or inefficient power usage across your site. This allows you to make onsite adjustments to your machines, increase power efficiency and saving money.

LoraWAN

El-Björn CONNECT devices communicate wirelessly using a LoRaWAN signal. This signal has longer range capabilities able to penetrate thicker walls and underground structures compared to standard mobile data signals, providing a more reliable machine data.

How El-Björn CONNECT works:

Gather Data

Your El-Björn machines wirelessly communicate performance data via an onsite gateway unit to your personal online portal.

Visual Display

Your online portal allows you to view your real time and historic machine performance data. This portal can be personalised for you to your site needs at any stage of your hire process.

Alerts/Notifications

Create performance alarms and push notifications alerting you to when a machine is operating outside of your required parameters, allowing you to make faster onsite changes.

Activity Scheduling

Create operating schedules for individual TF EBC machines that automatically change the set temperature, fan speed and power output at a time of your choosing.

Online Platform

Your easy to use portal allows you to remotely view your site performance anywhere in the world. Personalised dashboards can be created to better view your available data. Multiple users access is available which can be tiered or limited to specific project areas if needed.

Reports

Personalised performance reports can be create for you to to download at will. Reports can be created at any point of the rental period, able to extract data from the machines recorded performance on the project.

INDUSTRY LEADING BUILDING MANAGEMENT SYSTEM

El-Björn CONNECT is our Temporary Building Management System, offering remote monitoring of temporary climate control and power distribution units, all from one easy to use online portal.

Gather Data

Your El-Björn machines wirelessly communicate performance data via an onsite gateway unit to your personal online portal.

Visual Display

Your online portal allows you to view your real time and historic machine performance data. This portal can be personalised for you to your site needs at any stage of your hire process.

Alerts

Create performance alarms and push notifications alerting you to when a machine is operating outside of your required parameters, allowing you to make faster onsite changes.

Activity Scheduling

Create operating schedules for individual TF EBC machines that automatically change the set temperature, fan speed and power output at a time of your choosing.

Online Platform

Your easy to use portal allows you to remotely view your site performance anywhere in the world. Personalised dashboards can be created to better view your available data. Multiple users access is available which can be tiered or limited to specific project areas if needed.

Reports

Personalised performance reports can be create for you to to download at will. Reports can be created at any point of the rental period, able to extract data from the machines recorded performance on the project.

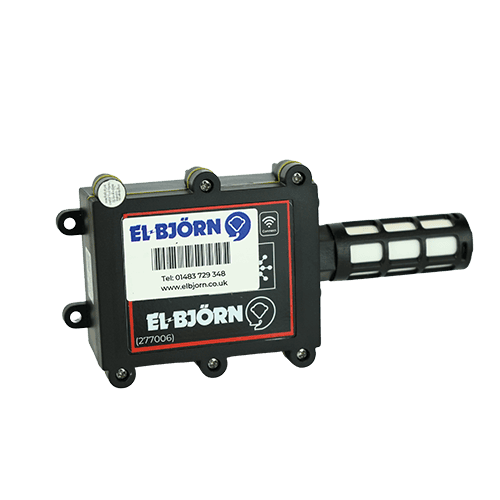

El-Björn CONNECT Products

El-Björn CONNECT Products

The El-Björn CONNECT BMS system is readily compatible with our TF EBC Industrial heating units and 1600A MOD.DU power distribution unit, and can be used to monitor other El-Björn climate and power units with the dedicated products below.

BOOK A DEMO